refrigeration compressors

-

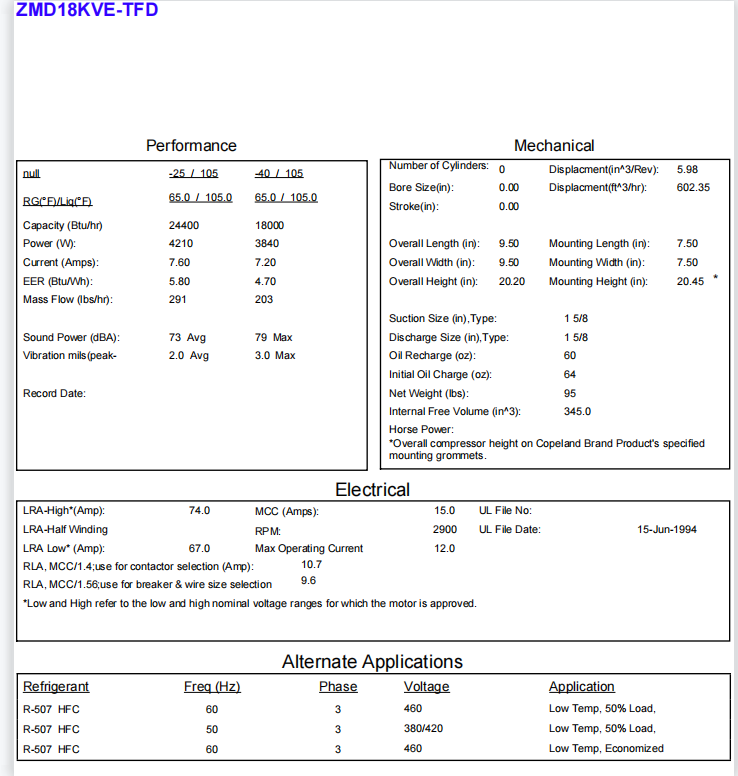

1020795 Thermo king compressors ZMD18KVE-TFD-275, copeland compressor for refrigeration

Thermo King design and build their own compressors specifically for the extreme demands of truck and trailer transport temperature control applications. Our compressors are built to last and are continuously developed to do justice to the high demands from customers.

Genuine Thermo King compressors are developed by dedicated teams of Thermo King engineers and tested extensively in state-of-the-art R&D centres for high performance and long life to keep you on the road for longer.

Key Features

- High efficiency and greater capacity

- Less noise and vibration

- Less maintenance (87% fewer moving parts)

- E nickel-plated Oldham coupling for greater Reliability

MONDEL NO: ZMD18KVE-TFD-275

Part No. : 102-0795

-

Thermo King Compressors ZMD18KVE-TFD-977, Thermo King refrigeration compressors , reefer parts

The thermo King compressor ZMD18KVE-TFD-977 is a highly efficient, reliable compressor used in refrigeration units designed for transporting temperature-sensitive cargo in reefer containers. This compressor operates with a nominal capacity of 18,000 BTU/H and is specifically designed to operate with R-404A refrigerant. The ZMD18KVE compressor features a scroll design that provides consistent cooling performance and is designed to operate in demanding environmental conditions. Some of the essential parts which you may require for the Thermo King compressor ZMD18KVE include oil filters, suction filters, gaskets, and drive belts. Additionally, you may also require electrical components and oil level sensors to keep your unit running smoothly.

ZMD18KVE is a scroll compressor from Thermo King designed for refrigeration applications in reefer units. It has a displacement of 51.8 m³/hr (305 CFM) with a maximum operating speed of 3,600 RPM. The compressor has a rated horsepower of 6Hp and uses R-404A refrigerant. It is known for its high efficiency, low noise, and vibration operation. The ZMD18KVE compressor is commonly used in small to medium-sized refrigerated units for transport and storage of perishable goods.

Thermo King design and build their own compressors specifically for the extreme demands of truck and trailer transport temperature control applications. Our compressors are built to last and are continuously developed to do justice to the high demands from customers.

40-ft refrigerated thermo king compressor ZMD18KVE ZMD26KVE reefer cooling parts containers carrier compressor

Genuine Thermo King compressors are developed by dedicated teams of Thermo King engineers and tested extensively in state-of-the-art R&D centres for high performance and long life to keep you on the road for longer.

thermo King compressor ZMD18KVE-TFD-977 Key Features

- High efficiency and greater capacity

- Less noise and vibration

- Less maintenance (87% fewer moving parts)

- E nickel-plated Oldham coupling for greater Reliability

thermo King compressor ZMD18KVE-TFD-977 specification

-

RSH105GD01,RSH105GR01 ,RSH105GA01, carrier r134a scroll compressor, reefer container 69NT40-541-001 compressor

carrier compressor, part NO. 18-10134-23 compressor scroll carrier parts for reefer

RSH105GD01,RSH105GR01horse power:10 hppower source: 440-460V/3/60Hz400v/3ph/50hzLRA:80refrigerant: r134a/r407c/r404aWhat should be paid attention to in cold storage insulation and energy conservation? carrier r134a scroll compressor RSH105GD01Due to the above characteristics of cold storage buildings, in addition to strict insulation, sealing, durability, and frost resistance in design and construction to ensure building quality, in daily use and management, scientific management and safe production should also be implemented based on the characteristics of the cold storage to extend its service life, reduce production costs, save maintenance costs, and improve enterprise economic efficiency. Cold storage is a special building used for food freezing and refrigeration, and to maintain low temperatures. Carrier compressors are used on ships, and thick axial flow fans are installed on the floors, walls, and roofs of the warehouse.carrier r134a compressor RSH105GD01Carrier compressors generate heat, and troubleshooting of Carrier compressors. From the perspective of energy conservation, it is necessary to minimize the startup time and number of units, However, in actual fruit and vegetable storage, the operation method that is both economical and product quality is: when entering the warehouse, all the axial flow fans are turned on, and the Carrier compressor accessories are used. After the temperature stabilizes, the number of opened units is reduced, and strict temperature requirements are imposed on the storage varieties. In order to ensure uniform temperature between the upper and lower parts, 1-2 axial flow fans are still kept in operation when the refrigeration and liquid supply are stopped. The moisture-proof layer and insulation layer of the compressor are generally evaluated using accelerated life test methods for the working life of the compressor.carrier compressor RSH105GD01Commonly used methods include 68t speed wear test, 1000h, 2000h or even longer life test, 2000 ‘, and hour life test, which can also assess the compatibility of various materials. -

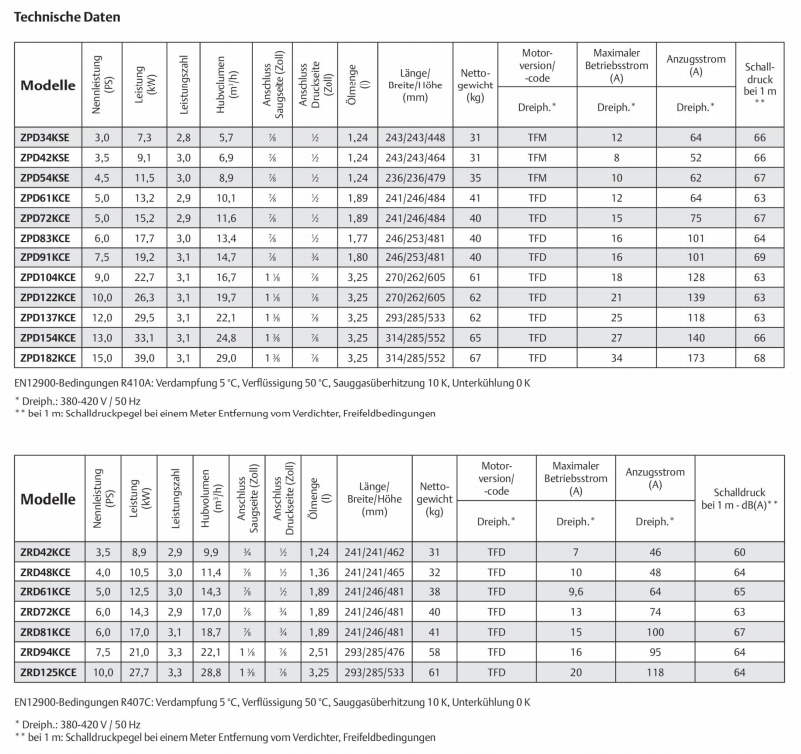

Copeland scroll digital compressor 6hp, 8hp, 12hp, ZPD61KCE ZPD72KCE ZPD122KCE

Copeland Scroll Digital compressor increases HVAC system efficiency via capacity modulation and provide energy savings by precisely matching compressor output to your heating or cooling needs. This technology is perfect for buildings or rooms which experience widely varying loads or where tight temperature and humidity control are needed.

copeland digital compressor comfort to match your needs

The Copeland scroll digital offers compressor modulation from 10-100 percent, allowing cooling systems to automatically adjust capacity as needed while reducing energy consumption. This scroll technology is up to 30 percent more efficient than traditional methods of system modulation.

The upgrade kit features the new Emerson Commercial Comfort Controller and the required valve, coil, thermistor, and tubing needed for a complete compressor replacement.

copeland digital compressor ZPD,ZRD series are in stock.

Cleaning method for household central air conditioning of copeland digital compressor refrigeration unit – Cleaning steps for household central air conditioning

1. Open the suction grille, hold the two buttons, and slowly pull them down at the same time

2. Pull the hook on the air filter diagonally downwards and remove the filter.

3. Cleaning method: Use a vacuum cleaner to remove dust, or clean with water or warm water. If there is too much dust, use a soft bristled brush and neutral detergent. After washing, shake off the water and then dry it in a cool place. Remember not to use hot water above 50 ℃ for cleaning to avoid discoloration or deformation; Do not dry on the fire as the filter may catch fire.

4. The air filter must be installed after cleaning. Hang the air filter on the protruding part of the upper part of the suction grille, and then fix it on the suction grille; Slide the convex handle on the back of the suction grille inward and install the air filter on the suction grille.

5. Close the suction grille, opposite to step 1, press the filter signal reset button on the control panel, and the reminder sign for central air conditioning cleaning will disappear. If there is excessive dust in the operating environment, the air filter should be cleaned approximately once every six months.copeland digital compressor factory direct sale, brand new

Model Number: ZPD122KCE-TFD-532

Weight (With Oil): 62KG

Approved Oil: COA 32E 200L

Oil Charge: 3.3L

Orginal : Thailand

Displacement: 19.7m3/h

copeland digital compressor many models are available

-

30hp Bitzer 6G-30.2-40P Compressor Commercial Refrigerator Compressor R134a in stock

Bitzer 6G-30.2-40P specification

Power: 22KW

Power: 380V/440V-50HZ/60HZ

Cylinder diameter (mm): 75

Stroke (mm): 55

Number of cylinders: 6

Exhaust volume: 126.8m3/h

Foot mounting size: 305mmx381mm

Dimensions (mm): length 790 width 503 height 443

Suction pipe inner diameter (mm): 54

Exhaust pipe inner diameter (mm): 35

Oil charge (liter): 4.75

Suitable for refrigerant: R134a R404A R507A R407CWe can also provide the following models

(一)4PCS-102(Y) 4PES-12(Y),4TES-12(Y) 4PES-12(Y) 4PES-15(Y)

4NES-14(Y) 4NES-20(Y) 4JE-15(Y) 4JE-22(Y) 4HE-18(Y)

4HE-25(Y) 4GE-23(Y) 4GE-30(Y) 6JE-25(Y) 6JE-33(Y)

6HE-25(Y) 6HE-35(Y) 6GE-30(Y) 6GE-40(Y) 6FE-40(Y)

6FE-50(Y) 8GE-50(Y) 8GE-60(Y) 8FE-60(Y) 4TCS-12.2(Y )

4PCS-10.2(Y) 4PCS-15.2(Y) NCS-12.2(Y) NCS-20.2(Y)4J-13.2(Y)

4J-22.2(Y) 4H-15.2(Y) 4H-25.2(Y) 4G-20.2(Y) 4G-30.2(Y)

6J-22.2(Y) 6J-33.2(Y) 6H-25.2(Y) 6H-35.2(Y) 6 G-30.2(Y)

6G-40.2(Y) 6F-40.2(Y) 6F-50.2(Y) 8GC-50.2(Y) 8GC-60.2(Y) 8FC-60.2(Y)

(二)two stage bitzer reciprocating compressors

S4G-12.2Y,S6J-16.2Y S4N-8.2Y

S6H-20.2(Y) S6G-25.2(Y) S6F-30.2(Y)

Bizer two-stage compressor rated power 4KW-44KW

This series of compressors is the result of extensive research and development based on years of experience in producing efficient and reliable piston compressors.

These compressors have been further developed and optimized for alternative refrigerants, especially HCFC R22, HFC R404A, and R507A, in some important details.

Using proven parts over the years, it is a product with a reliable structure that is widely used in a wide range of fields.

The matching of the airflow path and valve plate structure to cryogenic applications, coupled with the specially designed second generation motors and drive components for the highest efficiency, results in higher performance than previous cryogenic systems.

Universal compressor series for chlorine free HFC and HCFC’s refrigerants

Conversion to use HFC refrigerant:

● Use polyester oil approved by Bizer (compressor model suffix with “Y”) ● Match intermediate cooling expansion valve suitable for HFC refrigerant

Most important design features: □ Short gas path

● Large suction nozzle ● Minimum heat exchange □ Reliable valve plate design

● Impact resistant spring steel valve plate

Minimum space requirements

Extremely compact size design □ Low vibration and low noise

● 4-cylinder and 6-cylinder structures with optimized mass balance design, particularly quiet operation □ High cooling capacity and minimum energy consumption

● High efficiency working valve plate ● Minimum dead center clearance ● High efficiency large volume motor □ Durable drive components

● Eccentric shafts and crankshafts with hardened surfaces ● Sealed main bearing shells and large capacity oil pumps ● Patent oil return system ensures extremely low oil carryover rate ● Low friction bearing shells and aluminum pistons ● Piston rings with hard chrome plated surfaces ● Special crank pin bearing shells □ Pressure oil supply lubrication system

● Adopt gear oil pump that can work in both directions □ Large capacity built-in motor

● Gas cooling

Optimized rotor and stator sections with the highest efficiency and power factor □ IP54 protection grade junction box

Optional IP66 □ Electronic motor protection device

● Use PTC sensors to monitor motor temperature ● Exhaust temperature protection (optional) □ Built-in differential pressure safety valve □ Intermediate cooling liquid injection system

Optional mechanical TX valve

● Select an electronically controlled CIC system for R22

Options:

● Installed liquid subcooler ● Exhaust temperature protection sensor

● Motor protection device with additional functions (INT389) ● Crankcase heater ● Oil pressure protection switch ● Oil maintenance valve -

Air Conditioner Hitachi screw compressor 60ASCP-Z, Hitachi Ac Compressor,Hitachi Refrigerator Compressor 60hp

Hitachi screw chillers use the latest Hitachi twin screw compressor to improve the structure of the heat exchanger, comprehensively improving unit performance and efficiency.

Can provide a wide variety of application products:

Water cooled: low temperature dual working condition unit

(Minimum temperature can reach – 20 ℃)

Heat recovery models, water source heat pump units, etc

Air cooled: year-round operating models, hot water units

Ultra quiet unit (industry’s lowest noise

Horizontal), etc

Product refrigeration capacity range: above 45kWCompared with other types of compressors, Hitachi screw compressors generally have the following advantages, and are widely used in air conditioning, refrigeration, plant equipment, air heating, and other aspects.

① The screw compressor has few sliding parts, and there are no parts such as actuating valves that must be exchanged in a short period of time. Therefore, it has high reliability, and there is no need for long-term overhaul The structure is simple, and the number of main parts is about 1/10 of that of reciprocating type (compared to our company) Adopt double sealing structure, low noise.

④ The refrigerant compression is low vibration because it is compressed through continuous suction.

⑤ High efficiency, especially in low-temperature applications, air heat source cooling and heating, can play an outstanding performance. ⑥ There are two methods of capacity control: phased and continuous, which can widely adapt to different needs.

⑦ If liquid refrigerant is injected at the suction side of the compressor, the temperature of the discharged gas will not rise above 120 ℃. ⑧ Use a special synthetic lubricating oil that has a discharge temperature of 120 ° C and does not carbonize or deteriorate@ The starting load of the compressor is small. The motor can be started by using a small starting flow delta type( λ—— △)。60ASCP-Z hitachi compressor specification

Refrigerant: r22/R407Horse power(hp):60Voltage:380~415V/ 3PH/50hz220/240v-50hzcooling capacity (KW): 184.9Displacement(m3/h): 208.7oil charge: 6Lmotor: 45kw 2pnet weight: 460kg -

7.5HP scroll compressor JT224D-NYR air conditioning reefer container compressor

Model:JT224D–NYR

Horse power:7.5HP

Capacity:21500KW

Input power:7.66KW

COP (W/W):3.28

-

R404a Danfoss Maneurop Piston Refrigeration Compressor MTZ125–4VI , MTZ160HW4VE,MTZ100,MTZ64,MTZ144HV4VE

Compressor Model: MTZ125

Refrigrant: R404A

Refrigeration 50Hz ,EN12900 ratings

Cooling Capacity Btu/h: 53600

Power Input kW: 8.44

Current Input A: 13.79

E.E.R Bth/Wh: 6.35 -

15hp Performer Scroll compressor SM185 SM185S4CC SM185S4QC SM185S3QC

Nominal motor power [HP]: 15HP

Displacement [m³/h]]: 43.48

Gross/Net weight [kg]: 120/100

Oil charge [dm³]: 6.2

Power supply [V/~/Hz]: 380-420/3/50Hz

Locked rotor current [A]: 175

Max. operating current [A]: 32

COP (W/W): 3.34 -

-

copeland HVAC compressors all model numbers,chiller compressors

Product specification Nominal motor power [HP]: 6 Displacement [m³/h]]: 87.5 Sound pressure level : 77 Gross/Net weight [kg]: 50 Oil charge [dm³]: 1.95 Power supply [V/~/Hz]: 380-420/3/50Hz Locked rotor current [A]: 62 Max. operating current [A]: 32 Winding resistance [Ω]]: 0.37 Oil charge [dm³]: 1.95 Color : Black Packing: Wooden case or Pallet MOQ: 1pcs Compressor Condition:New HS : 8414301400 -

Copeland Refrigeration scroll compressor ZP235KCE-TWD-450 380-420V 3-Phase R410A

Performance

Evaporator Temp. (ºF) 45 45

Condensing Temp. (ºF) 130 100

Return Gas Temp. (ºF) 65 65

Liquid Temp. (ºF) 115 85

Capacity (Btu/hr) 235000 290000

Power (W): 21100 15400

EER (Btu/Wh): 11.10 18.80

Mass Flow (Ibs/hr): 3460 3590

Current (Amps): 30.60 23.60